How to Cut Aluminum Signage Parts with a CNC Engraving Machine

In the operation of a precision parts factory specializing in Swiss-type lathe machining, cutting aluminum signage parts with a CNC engraving machine is a key process that requires both precision and efficiency. Aluminum signage, valued for its light weight, corrosion resistance, and machinability, is widely used in identification, decoration, and various industries. The following details the specific process and key points of this technology based on the factory’s practical experience.

I. Pre-machining Preparations

1. Material Selection and Pretreatment

Selecting suitable aluminum sheets is crucial, with commonly used 6061 aluminum alloy offering good strength and machinability. The sheets must be flat, free of oxide scale and oil stains. For oil stains, use specialized aluminum cleaners with an ultrasonic cleaner; light oxide scale can be gently removed with fine sandpaper.

2. Design Drawing and Layout

Use professional drawing software (such as CorelDRAW, AutoCAD) to design the signage patterns. Set dimensions, fonts, and pattern details precisely according to design requirements. After design, reasonably layout multiple signage patterns on the sheet to maximize material utilization and reduce waste.

II. Parameter Setting and Tool Selection for CNC Engraving Machine

1. Parameter Setting

Spindle Speed: When cutting aluminum signage, set it at 10,000–15,000r/min to ensure a smooth cutting surface and reduce burrs.

Feed Rate: Typically 1,000–2,000mm/min, adjusted flexibly based on the signage complexity and cutting depth. Lower the feed rate for complex patterns to ensure precision.

Cutting Depth: Depending on the aluminum sheet thickness, control single-pass cutting depth at 0.5–1mm; use layered cutting for thicker sheets.

2. Tool Selection

Recommend carbide tools, such as 3mm or 6mm single-flute spiral milling cutters. These tools feature strong wear resistance and sharp cutting edges, effectively ensuring cutting quality and extending tool life.

III. Cutting Operation Process

1. Clamping the Sheet

Clamp the pretreated aluminum sheet flat on the CNC engraving machine’s worktable using pressure plates or a vacuum chuck to ensure no displacement during cutting. After clamping, use a tool setter to precisely measure the relative position between the tool and the sheet, and set the workpiece coordinate system.

2. Program Import and Simulated Operation

Import the typeset cutting program into the CNC engraving machine’s control system. Before formal cutting, run a simulation to check for tool path collisions or interferences, ensuring a safe and error-free cutting process.

3. Formal Cutting

Start the CNC engraving machine for cutting once all preparations are complete. During cutting, monitor the engraving machine’s operation in real time, including spindle speed, feed rate, and other parameters for stability. Observe the cutting surface quality and promptly handle anomalies like tool wear or breakage.

IV. Post-processing and Quality Inspection

1. Post-processing

After cutting, the aluminum signage parts may have residual burrs or debris. Use methods like brush cleaning, deburring machine grinding, or chemical polishing to achieve the required surface finish.

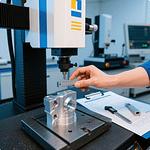

2. Quality Inspection

Use detection tools such as calipers and projectors to strictly inspect the signage parts for dimensional accuracy, pattern integrity, and surface roughness. Control dimensional tolerance within ±0.1mm and surface roughness below Ra3.2μm to ensure products meet quality standards.

With the above scientific and standardized processing procedures and strict quality control, our factory delivers high-quality aluminum signage parts to meet diverse needs across industries.