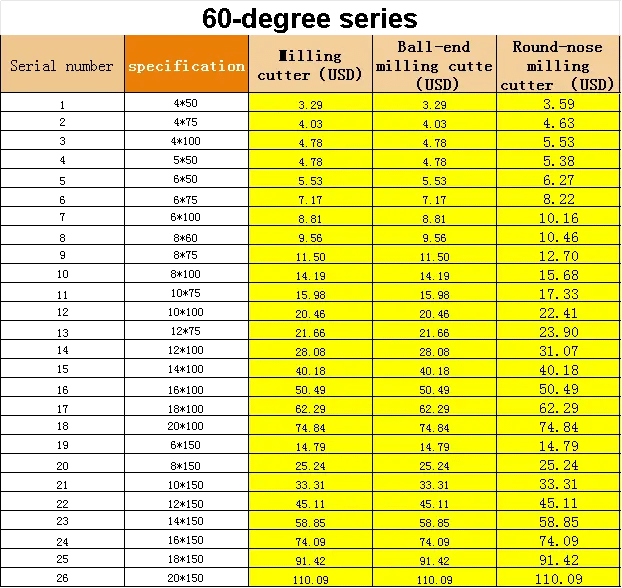

60° series milling cutters

The 60° series milling cutters are widely used cutting tools in the field of mechanical processing. The angle of its cutting edge is designed to be 60°, and this angle design endows the milling cutters with unique cutting performance. This series of milling cutters are usually made of high-quality high-speed steel or cemented carbide materials, possessing relatively high hardness and wear resistance, and can maintain a good cutting edge shape and sharpness during long-term cutting operations.

Feature:

Precise machining ability, good distribution of cutting forces, high hardness and wear resistance (for cemented carbide materials), good toughness (for high-speed steel materials), wide application range, high processing efficiency

Machining Precision:

Dimensional accuracy: High-precision manufacturing processes and stable material properties.

Shape accuracy: Precise cutting edge angles and good tool rigidity.

Surface roughness: High-quality tool coatings and reasonable cutting parameters.

Positional accuracy: High-precision clamping systems and advanced processing equipment.

The tolerances of some high-end 60° series milling cutters in key dimensions such as cutting edge diameter and shank diameter can be controlled within a very small range, for example, within ±0.005mm, thus ensuring precise cutting during the machining process and meeting the dimensional requirements for the processing of precision parts.

Machining Process:

Select appropriate raw materials according to the performance requirements of milling cutters, such as high-speed steel (HSS) or cemented carbide. Ensure that the hardness of the raw materials meets the standards through hardness testing equipment, and use a spectral analyzer to detect whether the chemical composition is accurate. If high-speed steel materials are used, forging processes are required. For cemented carbide milling cutters, the powder metallurgy process is adopted to manufacture blanks. Use CNC grinding machines or ordinary grinding machines to conduct rough machining on the blanks, and utilize high-precision grinding machines, such as five-axis simultaneous grinding machines, to perform precision grinding on the cutting edges. Carry out special treatments on the cutting edges, such as chamfering or passivation treatments. Select appropriate coating materials according to the application scenarios and processing requirements of milling cutters, and use high-precision measuring tools, such as coordinate measuring machines, to detect the dimensional accuracy of milling cutters.

Product Application:

During the machining process, the 60° series milling cutters are suitable for milling a variety of materials, such as metallic materials (including steel, aluminum, etc.) and some composite materials. They can efficiently remove materials and realize multiple processing techniques like milling the surface of workpieces, contour machining, and slotting. Its precise 60° angle helps to obtain relatively accurate machining dimensions and good surface roughness. Compared with other milling cutter series, the 60° series milling cutters demonstrate unique advantages in certain machining tasks with specific shapes and precision requirements. They can meet the needs for high-precision and high-efficiency machining in industrial production, and thus are widely used and recognized in numerous industries such as mechanical manufacturing, aerospace, and the automotive industry.

Our Team have focused on machining industry for 20 years,Production and sales of precision machinery parts,We have strong machinery manufacturing capacity, strong inspection equipment,mostof the parts were used for automotive.

The machines can meet your strict customized requirements for the machining tolerance , product quality and delivery time, with the brand of Tomos, Star Citizen. We have strong machinery parts manufacturing capacity, strong inspection equipment, most of the parts were used forautomotive,with the certification of lATF 16949. We provide a wide range of material options, the metal bars is our usual option, such as stainless steel, copper, brassaluminum and so on. Some multiple plastics is also our options.

Question and answer

OEM / ODM Services

Vacuum table

Rotary axis

Handwheel

Lubrication device

Tool Magazine

Spindle

Suzhou Changfei Precision Machinery Co., Ltd.

Why Clients Choose Us

ServicesOEM | Design | Buyer Label

Product lineAbove 10 production line

Total Employees80 - 120 People

Factory5,000-10,000 square meters

Customer Review

They accepted my request to use VHB tape for sticker,nice work,This is the mold to produce the part as my request.

Great prototype sample,Provide QC report and photos before shipping, nice service.

he CNC of the product is very superb and accurate, the surface is very clea.

Product arrived and it was perfect according to our engineer's measurements of the product.

Shipping Method

SHIP VIA EXPRESS DELIVERY

Ship products via sea