How to Prevent Parts from Moving on CNC Milling Machines

In the field of Swiss-type lathe precision machining, part displacement is a critical issue. For a 0.5mm thin-walled medical part, displacement exceeding 0.01mm can spike the rejection rate to over 15%. Such problems mainly arise from insufficient fixture rigidity, cutting vibration, or clamping stress. However, scientific anti-displacement strategies can control positioning errors within ±0.003mm. The following details the full-process control solutions based on our factory’s 12 years of practical experience in tooling design and process optimization.

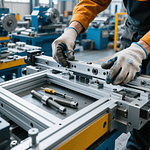

I. Reinforced Tooling Fixture Design

(1) Multi-Contact Clamping Solutions

1. Petal-type Jaws: Our 6-lobe elastic jaws (opening 0.03–0.15mm) improve clamping force uniformity by 40%, making them ideal for φ2–8mm shaft parts. In machining precision shafts for automotive engine fuel injection systems, these jaws stabilize the workpiece to ensure machining accuracy.

2. Vacuum Adsorption Platform: For 1mm-thick aluminum automotive radiator fins or aluminum components of medical ultrasound probes, we use porous ceramic suction cups (pore diameter 0.2mm, vacuum degree ≥-0.09MPa), covering over 90% of the part’s bottom surface for secure adsorption.

(2) Rigid Support Structure

1. Three-point Positioning Blocks: When machining automotive steering shafts or hydraulic pump shafts, we install cemented carbide support blocks (hardness HRC65) axially on parts to form a stable triangular support structure, enhancing part stability during machining.

2. Damping Cushion: Inlaying neoprene pads (Shore A 50–60) at the fixture base reduces vibration amplitude by over 55%. For example, when machining slender rods for medical surgical instruments, this ensures machining precision.

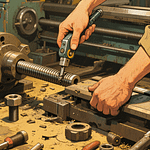

II. Cutting Process Vibration Control

(1) Tool and Parameter Matching

1. Steel Parts Machining: Ceramic tools are suitable for machining steel connecting rods of automotive engines or hydraulic valve blocks. The spindle speed can be set at 18,000–22,000r/min, and the feed rate at 0.01–0.025mm/r to control cutting force and vibration while ensuring efficiency.

2. Aluminum Parts Machining: PCD tools excel in milling automotive aluminum alloy wheel hubs or aluminum casings of medical devices. Increasing the spindle speed to 25,000–30,000r/min and feed rate to 0.008–0.02mm/r significantly shortens processing time while maintaining surface quality.

(2) Cutting Force Balance Technology

1. Symmetric Milling: When machining gear shafts of automotive transmissions or hydraulic cylinder bodies, dual-spindle synchronous machining (e.g., simultaneous milling of both end faces) counteracts radial cutting forces, reducing part deformation and improving precision.

2. Spiral Tool Entry: Using a G03 arc entry (radius R3mm) instead of vertical entry for machining threaded holes of medical implants or complex cavities of automotive parts reduces cutting impact force by 30%, minimizing displacement risks.

III. Clamping Process Optimization

(1) Stress Release Preprocessing

1. Preload Positioning: When clamping automotive brake discs or key medical device components, apply 0.5–1N preload and monitor deformation with a dial indicator (≤0.005mm) to eliminate stress that may cause part displacement in advance.

2. Temperature Compensation: When machining precision valve parts of hydraulic systems, control the temperature difference between the fixture and parts within ±2℃ to prevent displacement caused by thermal deformation.

(2) Soft Contact Clamping

1. Silicone Gaskets: Install 0.1mm-thick silicone pads on fixture contact surfaces when machining medical bone screws or aluminum alloy pistons of automotive engines to prevent indentation on thin-walled parts and provide buffering for stable clamping.

2. Torque Control: Use torque wrenches (accuracy ±3%) to control jaw tightening force. For example, when machining automotive steering knuckles or hydraulic pump gears, precise clamping force control avoids deformation or displacement due to overpressure.

IV. Intelligent Monitoring System

(1) Real-time Displacement Monitoring

1. Laser Vibrometer: A laser vibrometer with a sampling frequency of 10kHz monitors part vibration displacement with an accuracy of ±0.002mm, detecting minute displacements in real time during machining of automotive or medical device parts.

2. PLC Linkage: When the laser vibrometer detects displacement exceeding the threshold, the PLC system automatically reduces the feed rate by 15–30% to adjust the machining state and prevent intensified displacement.

(2) Force Feedback Clamping

1. Strain Gauge Sensors: Embedded in jaw contact surfaces with a resolution of 0.1N, these sensors display real-time clamping force fluctuations, enabling real-time monitoring during machining of automotive engine crankshafts or high-precision gears of medical devices.

2. Automatic Compensation: When strain gauge sensors detect clamping force fluctuations due to cutting forces, servo motors dynamically adjust jaw pressure to compensate for displacement caused by cutting forces, maintaining stable clamping.

Typical Case: Anti-Displacement for 0.8mm Stainless Steel Medical Tubes

1. Tooling Scheme: 6-lobe jaws (clamping force 2.5N) with 0.2mm silicone pads and three-point support blocks spaced 15mm provide a stable clamping environment for 0.8mm stainless steel medical tubes.

2. Cutting Parameters: PCD tool, speed 28,000r/min, feed rate 0.015mm/r, spiral entry angle 15° to control cutting force and vibration.

3. Monitoring Data: Laser vibrometry shows maximum displacement of 0.004mm, with a part qualification rate of 99.3%.

4. Optimization Effect: Compared with traditional clamping, the rejection rate due to displacement is reduced from 12% to 0.7%, significantly improving productivity and product quality.

Preventing part displacement on CNC milling machines requires integrating tooling innovation, process optimization, and intelligent monitoring. Equipped with advanced laser interferometers and five-axis machining centers, our factory offers one-stop services from fixture design and process debugging to whole-line monitoring. With rich experience in automotive, hydraulic, and medical industries, we have processed over 800,000 precision parts. Our anti-displacement technology is certified by ISO 9001, ensuring zero-displacement delivery of high-quality products to customers.