How to Perform CNC Machining for Small Parts

In our factory specializing in precision parts machining with Swiss-type lathes as core equipment, CNC machining of small parts is a task requiring high precision and professional technology. Small parts are widely used in electronics, medical, aerospace and other fields. With their tiny size and complex structure, they have extremely high requirements for machining accuracy and surface quality. The key processes and practical techniques for CNC machining of small parts are described in detail below.

1. Preparations: Equipment and Process Planning

First, select appropriate machining equipment according to the characteristics of small parts. The Swiss-type lathes in our factory, with their high precision, stability and multi-axis linkage function, become the ideal choice for small parts machining. Swiss-type lathes can complete multiple processes such as turning, milling and drilling in one clamping, which greatly reduces errors caused by multiple clampings and ensures the machining accuracy of small parts.

Next, conduct an in-depth analysis of part drawings to clarify requirements for dimensional accuracy, geometric tolerance and surface roughness. For example, the pins of electronic connectors not only require micron-level diameter accuracy but also ensure a smooth surface without burrs. Then, use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to plan a reasonable machining process path, determine tool types, cutting parameters, etc., and generate CNC machining programs.

2. Key Machining Links: Tooling and Clamping

Tool selection for small parts machining is crucial. Due to the small size of parts, micro-tools such as micro end mills and drills with a diameter of 0.1 – 1mm are required. Tool materials are usually cemented carbide or diamond-coated tools to ensure tool wear resistance and sharpness, reducing the impact of cutting force and heat on parts.

In terms of part clamping, small parts are prone to deformation and difficult to position, so special clamping methods are needed. For small parts with regular shapes, vacuum chucks or precision machine vices can be used for clamping; for irregular or thin-walled parts, custom fixtures are required to ensure firm clamping without damaging parts. During clamping, strictly control the clamping force to avoid part deformation caused by excessive force.

3. Machining Process: Parameter Control and Real-time Monitoring

During machining, reasonable setting of cutting parameters is the key to ensuring machining quality. Generally, small parts machining requires high spindle speeds (10,000 – 50,000 r/min) and small feed rates (50 – 500 mm/min) to reduce cutting force and part deformation. The cutting depth should also be controlled within a small range, no more than 0.5mm for rough machining and 0.05 – 0.1mm for finish machining.

Meanwhile, use the machine’s real-time monitoring system to dynamically monitor the machining process. Sensors provide real-time feedback on data such as cutting force and spindle vibration. Once abnormalities are found, immediately adjust machining parameters or stop for inspection to prevent part scrapping. For example, when the cutting force suddenly increases, it may be due to tool wear or chip blockage, requiring timely tool replacement or chip cleaning.

4. Quality Inspection and Optimization

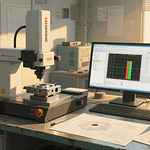

After machining, use high-precision inspection equipment to comprehensively inspect small parts. Common inspection tools include coordinate measuring machines, image measuring instruments, roughness testers, etc., which can accurately measure part dimensions, shapes and surface quality. Compare the inspection results with the drawing requirements. If dimensional deviations or surface defects are found, analyze the causes, adjust machining process parameters or optimize tool paths for re-machining.

CNC machining of small parts is a process that requires extremely high precision and attention to detail. In our factory, with advanced Swiss-type lathe equipment, a professional technical team and a strict quality control system, we are always committed to providing customers with high-precision and high-quality small parts machining services to meet the rigorous requirements of different industries for precision small parts.