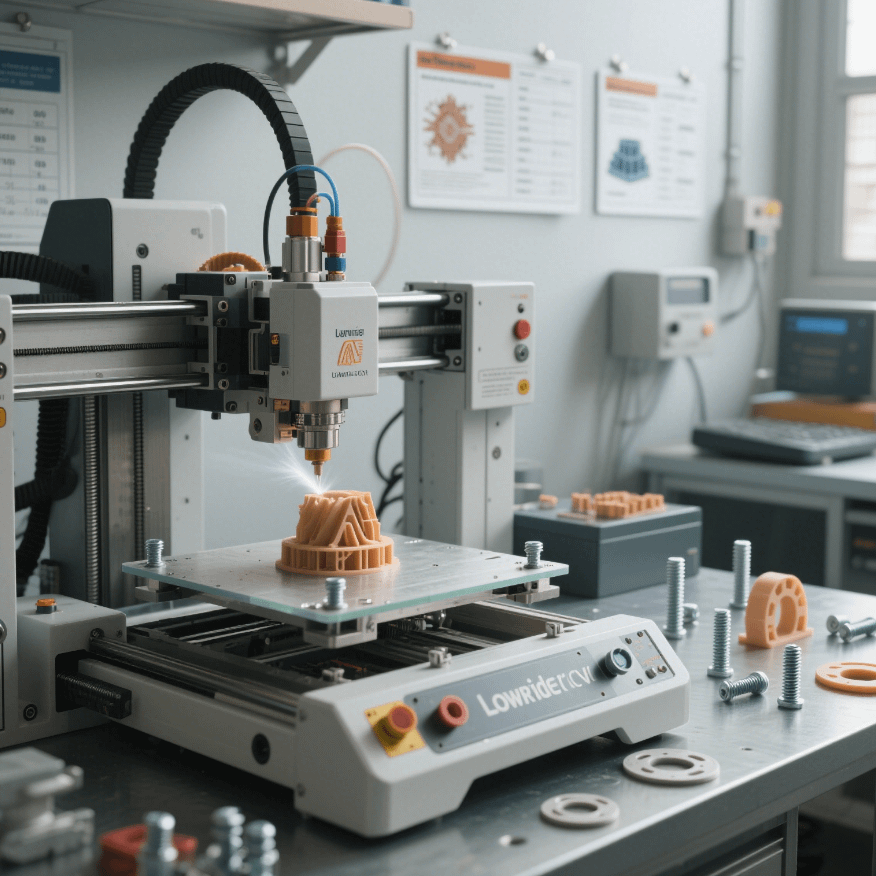

How Long Does It Take to Print Lowrider CNC Parts?

During our process of machining precision parts using Swiss-type lathes, many customers often inquire about the time it takes to 3D print Lowrider CNC parts. As an open-source CNC machine, the printing time for Lowrider CNC parts is not fixed. It is comprehensively influenced by various factors such as the size of the part, the complexity of its structure, the printing precision, the characteristics of the printing material, and the performance of the printing device.

The size of the part is an intuitive factor affecting the printing time. For smaller Lowrider CNC parts, such as connecting components like screws and gaskets, due to their small volume and low material consumption, the printing process is relatively quick. With a common desktop 3D printer, under normal settings, such small parts can be printed within 30 minutes to 1 hour. However, for larger parts, such as the frame beams or large bases of the Lowrider CNC, since a large amount of material needs to be stacked layer by layer, the printing time will significantly increase, and it may even take 12 to 24 hours to form.

The complexity of the part also plays a crucial role. For simple and regular parts, such as a rectangular support block, the printing path planning is simple, and the printing speed is relatively fast. But for parts with hollow structures or complex curved surfaces, the 3D printer needs to continuously adjust the movement trajectory of the nozzle, increasing the complexity and time of printing. For example, when printing a transmission part with an internal honeycomb hollow structure, compared with the same part with a solid structure, the printing time may be extended by more than 50%.

The impact of printing precision on time should not be underestimated. The higher the precision, the thinner the thickness of each printed layer. The printer needs to control the material deposition more meticulously, and the printing speed will naturally decrease. When the printed layer thickness is adjusted from 0.2 millimeters to 0.05 millimeters, although the surface of the part will be smoother and the dimensional accuracy will be higher, the printing time may be extended by 3 to 4 times. For key parts in the Lowrider CNC, such as motion bushings that require precise fitting, in order to ensure their adaptability with other components, a relatively high printing precision is often required, which will undoubtedly significantly increase the printing time.

The characteristics of the printing material also affect the printing duration. PLA material is a common 3D printing material with good fluidity and fast cooling speed, resulting in relatively high printing efficiency. However, ABS material requires a higher printing temperature and better cooling conditions, and the printing process is relatively slow. In addition, for some special materials, such as carbon fiber reinforced materials, higher requirements are placed on the printing equipment and process, and the printing time will increase accordingly. Moreover, if problems such as material clogging or warping occur during the printing process, the printing needs to be paused for adjustment, further prolonging the overall time consumption.

The performance of the printing equipment is equally important. High-end 3D printers have a faster nozzle movement speed, a more stable printing platform, and a more precise control system. When printing the same part, compared with ordinary printers, they can save 20% to 30% of the time. At the same time, reasonably optimizing the parameters in the printing software, such as the design of the support structure and the filling density, can also improve the printing efficiency to a certain extent.

Overall, for small Lowrider CNC parts with a simple structure, low precision requirements, and the use of conventional materials, the printing can be completed in approximately 1 to 2 hours. However, for large parts with a complex structure, high precision requirements, and the use of special materials, the printing time may be as long as 24 hours or even longer. In actual production, we will comprehensively consider various factors and formulate the optimal printing plan to ensure that the printing cycle is shortened as much as possible while meeting the quality requirements of the parts, so as to provide customers with efficient services.