How to Order CNC Machined Parts

In the field of precision manufacturing, efficient ordering of CNC machined parts is crucial for ensuring production continuity. Every step from requirement confirmation to acceptance directly impacts part accuracy and delivery cycles. As a factory with 10 years of Swiss-type lathe machining experience, we have summarized a standardized ordering process that reduces communication costs by 40% and improves on-time delivery rates to over 95%. The following is a detailed guide.

I. Requirement Clarification Stage

1. Technical Parameter Preparation

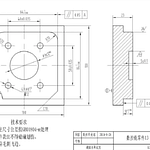

* Drawing Requirements: Provide CAD/STEP format drawings, marking key parameters such as tolerances (e.g., ±0.005mm) and surface roughness (Ra0.8μm);

* Material Selection: Specify materials (e.g., 304 stainless steel, 7075 aluminum alloy) and heat treatment requirements (e.g., T6 aging treatment).

2. Process Communication

* Machining Methods: Confirm whether processes like Swiss-type lathe or five-axis 联动 (five-axis linkage) are adopted;

* Batch Planning: Indicate the number of samples, small batches (≤1000 pieces), or large batch requirements.

II. Supplier Screening and Evaluation

1. Qualification Verification

* Certification System: Prioritize factories certified by ISO 9001 and IATF 16949;

* Equipment Strength: Verify the availability of high-precision Swiss-type lathes, coordinate measuring machines, and other equipment.

2. Case Validation

* Industry Experience: Review the supplier’s successful cases in automotive, medical, and other fields;

* Sample Testing: Request samples of similar parts to inspect dimensional accuracy and surface quality.

III. Order Confirmation Process

1. Contract Details

* Delivery Terms: Clarify lead times (e.g., 20 working days), transportation methods, and packaging requirements;

* Acceptance Standards: Agree on sampling ratios (e.g., 5%) and 不合格品 (non-conforming product) handling plans.

2. Price Negotiation

* Cost Composition: Understand itemized quotations for materials, processing, and testing;

* Volume Discounts: Negotiate tiered pricing (e.g., 8% discount for orders over 5000 pieces).

IV. Production Follow-up and Acceptance

1. Progress Tracking

* Milestone Feedback: Require suppliers to provide weekly processing progress photos or videos;

* Key Process Confirmation: Conduct process audits for heat treatment, surface treatment, and other key processes.

2. Quality Acceptance

* Inspection Reports: Review dimensional inspection reports and material certificates during acceptance;

* On-site Verification: Re-measure key dimensions using tools like micrometers and roughness testers.

Typical Case: Ordering Automotive Sensor Parts

1. Requirement Submission: The customer provided 304 stainless steel drawings with ±0.01mm tolerances, requesting 3 samples and 2000 pieces/month for mass production;

2. Supplier Selection: Our factory won the bid with ISO 9001 certification and automotive industry experience, providing inspection reports of similar parts as references;

3. Delivery Results: Samples delivered in 3 days, 100% on-time delivery for mass production orders, and a customer sampling pass rate of 99.7%.

Efficient ordering of CNC machined parts requires systematic processes and cooperation with professional suppliers. Equipped with 12 Swiss-imported Swiss-type lathes and fully automatic inspection lines, our factory undertakes high-precision shaft and complex cavity part machining, offering one-stop services from drawing optimization and prototyping to mass production to ensure high-quality order delivery.