How to Build Your Own CNC Machine Tool

In our factory that specializes in machining precision parts using Swiss-type lathes, having a deep understanding of the structural principles and the building process of CNC machine tools not only helps optimize production but also sparks innovation. For enthusiasts or professionals who want to explore the mysteries of CNC machine tool manufacturing, building a CNC machine tool of their own is a challenging yet highly rewarding task. Here is a detailed introduction to the key steps in building a CNC machine tool.

First and foremost, it is crucial to clearly define the design requirements. You need to determine key parameters of the CNC machine tool, such as its type (e.g., lathe, milling machine, or machining center), the number of axes (three-axis, four-axis, or five-axis), and the size of the worktable, based on the type of parts to be machined and the precision requirements. For example, if you mainly machine small precision parts, a compact three-axis CNC milling machine may be a suitable choice. If complex curved surface machining is involved, a machine tool with multi-axis linkage should be considered.

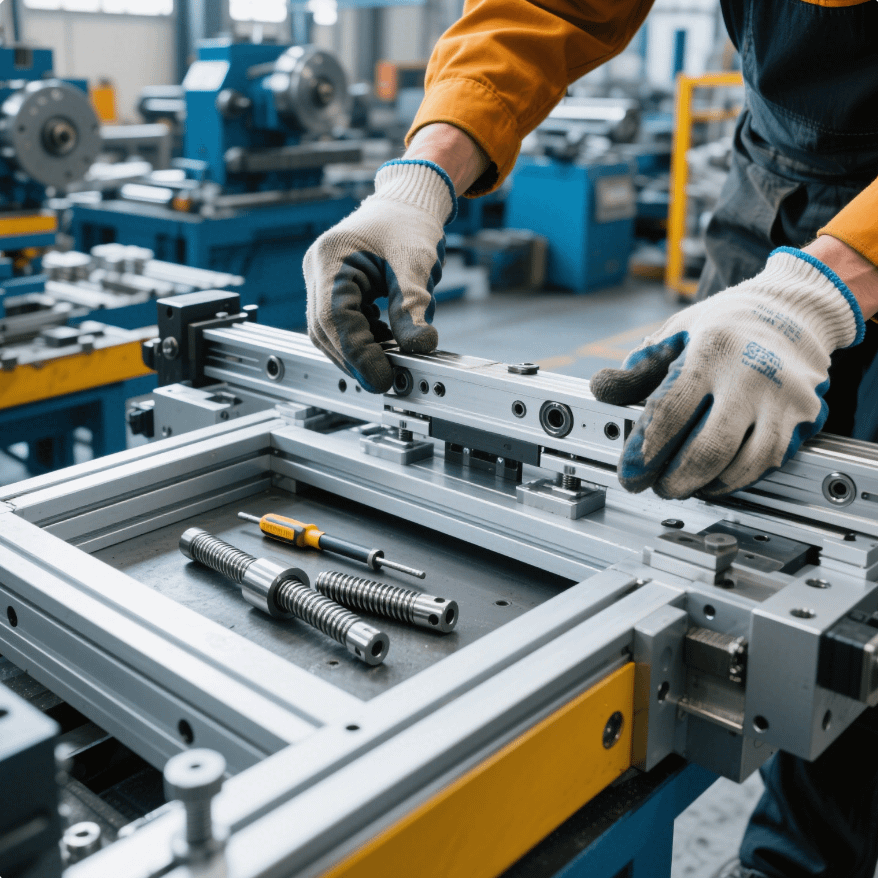

Next is the selection and procurement of hardware components. The main structure of the machine tool serves as the foundation. Cast iron or steel structures can be chosen to ensure good rigidity and stability. In terms of the motion system, linear guides and ball screws can ensure high-precision linear motion, while servo motors and drivers provide power and precise motion control for the machine tool. The control system, acting as the “brain” of the CNC machine tool, can be an open-source control system (such as GRBL, LinuxCNC) or a commercial CNC system, depending on your technical capabilities and budget. Additionally, don’t forget to prepare auxiliary components such as cutting tools, fixtures, and sensors, which are equally crucial for the normal operation and machining accuracy of the machine tool.

Once the hardware is ready, it’s time for the assembly stage. According to the design drawings, first build the main frame of the machine tool and install the linear guides and ball screws to ensure installation accuracy. Then, precisely connect the servo motors to the transmission mechanism to ensure smooth power transmission. When installing the control system, follow the instructions strictly for wiring and debugging to ensure stable signal transmission between components. After the hardware assembly is completed, conduct a comprehensive mechanical and electrical inspection to eliminate potential problems.

After the assembly is finished, software configuration is essential. Install the corresponding control software according to the selected control system and set parameters, such as motor parameters, the movement range of the axes, and the settings of limit switches. Then, use computer-aided design (CAD) software to model the parts, and through computer-aided manufacturing (CAM) software, convert the design model into a numerical control machining program that can be recognized by the machine tool. Before formal machining, be sure to conduct simulation to check the correctness of the program and the tool path to avoid collisions and interferences.

Finally, perform debugging and optimization. Gradually test various functions of the machine tool, from single-axis motion to multi-axis linkage, and observe the motion accuracy and stability. Cut sample parts for testing, detect the machining accuracy, and adjust and optimize the parameters of the machine tool and the machining program according to the test results. Repeat this process until the machine tool achieves the expected machining performance.

Building your own CNC machine tool is a process that combines theory and practice in depth. Although the process is challenging, every successful debugging and improvement will give you a deeper understanding of the operating principles and machining processes of CNC machine tools. In our factory, we always adhere to the spirit of exploration and innovation, continuously optimize the machining technology, and provide customers with higher-quality precision parts machining services.