CF Precision

Focused on

manufacturing precision

partpart parts for 10 years

Production and sales of precision machinery parts

Strong machinery manufacturing capacity, inspection equipment, most of the parts were used for automotive.

Autoparts Field

Brake/Engine

Automatic

→

Custom Design

Connector

OEM →

Online After-Sales

Online-Sales

Response →

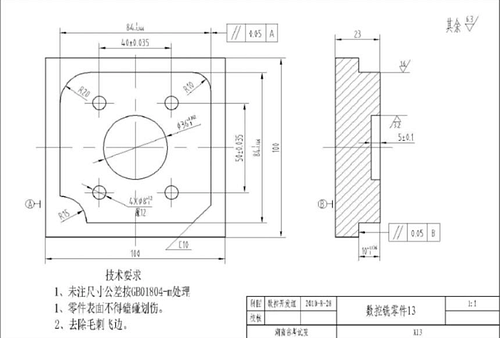

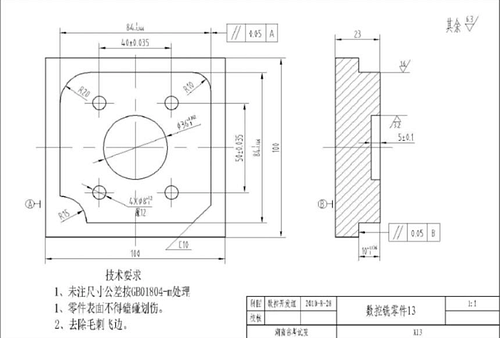

We provide CNC machining services of various complexities and can produce small-batch and large-batch components. Our Instant Quoting Engine can provide you with a quotation for CNC machining services in just a few seconds. Then, we will complete the processing of metal or plastic parts and deliver them to your door within a maximum of 10 days. We will inspect the produced parts to ensure product quality. Obtaining a quotation for CNC machining services is very simple: just upload a file of drawings, 3D models or sketches (supports various common formats).

Medical Products

Implantable Medical Devices The Surgical implants such as joint prosthetics , single-use sterile medical devices and hearing aids.

Energy Engineering

Renewable Energy Equipment Solar energy, geothermal energy, wind energy, ocean energy, biomass energy, and nuclear fusion energy.

Automotive Parts

Processing And manufacturing Molding, production, and processing of relevant molds for vehicle components now.

Industrial Control

Industrial Production Facilities. Industrial Control Equipment: Water pumps, valves, software, and auxiliary equipment.

Aerospace

Electrical Systems Development and design of electronic components, automatic control and testing equipment.

5G Communication

5G Robots Application Industrial robots, inspection robots, mobile robots, and cloud robots embedded with 5G modules.

BUSINESS REVIEW

Shows that there was a revenue of ¥30 Million in FY 2022.

OWNERSHIP

Strong manufacturing capacity, inspection equipment.

EMPLOYEES

More than 50 turing machines and about 50 employees

Advantages

Focused on machining industry for 20 years.

Quality Control

Precision machining parts for automotive

Product Certification

Most used forautomotive,with the certification of lATF 16949.

What we service

includes a range of advanced tools such as coordinate measuring machines, optical comparators

Strong Manufacturer

Produce various hardware cutting parts/special metal components.

With strong manufacturing capabilities, highly scalable and standardized production, sales network, after-sales service, and high-level customer support, we have earned a good reputation and image in an increasingly competitive market.

Focus Quality

have strong machinery manufacturing capacity, strong inspection equipment.

Production and Testing Equipment: 30 Taiwan automatic lathes and automatic feeders, 6 Japan STAR CNC Swiss-type automatic lathes, 4 projectors, microscopes, ultrasonic cleaning machines, torque testers, and tensile testers.

Production Capacity: Approximately 30 million pieces per month.

After-Sales Service

Quickly feedback for all the questions and requirements from all partners.

Zero-defect is always been our pursue.We take responsibility for the result for our doings.Our Team have focused on machining industry for 20 years,company adheres to the quality policy of "superb technology, superior quality, customer first, and satisfying service".

Inspection Equipment

includes a range of advanced tools such as coordinate measuring machines, optical comparators

Profile Measure Machine

Roundness Measure Machine

Auto Measure

Projector Measure

Auto Dimension Measure Machine

Caliper/ Micrometer/Microscope

OEM / ODM Services

Specializing in OEM/ODM machining and turning processes, particularly for components designed for leakage testing

Vacuum table

Lubrication device

Rotary axis

Tool Magazine

Handwheel

Spindle

ChangFei News

Tech info update

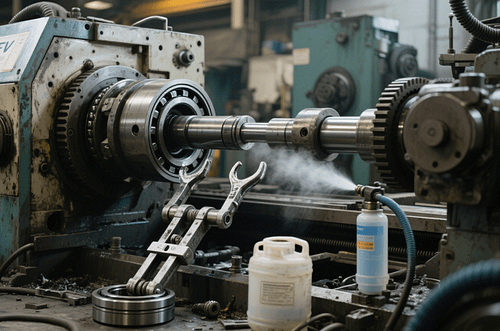

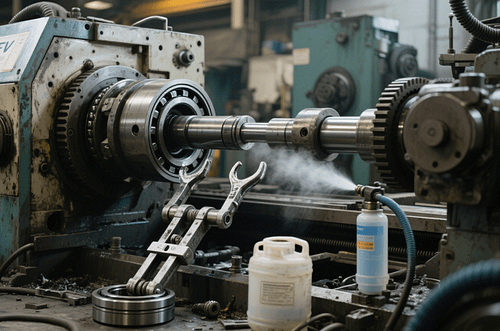

How to Replace CNC Spindle Bearings: A Comprehensive Technical Guide

How to Replace CNC Spindle Bearings: A Comprehensive Technical Guide I. Preparations Before Replacement1. Tools and Consumables* Essential Tools: Bearing puller, hydraulic press, electromagnetic induction heater

How to Program Parts in CNC Systems

How to Program Parts in CNC Systems In the field of Swiss-type lathe precision machining, the accuracy of CNC system programming directly determines part precision and

How to Order CNC Machined Parts

How to Order CNC Machined Parts In the field of precision manufacturing, efficient ordering of CNC machined parts is crucial for ensuring production continuity. Every step

How to Dismantle a CNC Lathe

How to Dismantle a CNC Lathe During equipment upgrading or relocation, standardized dismantling of CNC lathes is crucial to ensure the precision of secondary use. Improper

How to Replace CNC Spindle Bearings: A Comprehensive Technical Guide

How to Replace CNC Spindle Bearings: A Comprehensive Technical Guide I. Preparations Before Replacement1. Tools and Consumables* Essential Tools: Bearing puller, hydraulic press, electromagnetic induction heater

How to Program Parts in CNC Systems

How to Program Parts in CNC Systems In the field of Swiss-type lathe precision machining, the accuracy of CNC system programming directly determines part precision and

Company Information

Who we are

Suzhou Changfei Precision Machinery Co., Ltd.

We have strong machinery parts manufacturing capacity, strong inspection equipment, most of the parts were used forautomotive,with the certification of lATF 16949.

Our team have more than 20 years experience for the turning and machining process. Quickly feedback is one of our development standard. We have more than 50 turing machines and about 50 employees in our factory.The machines can meet your strict customized requirements for the machining tolerance , product quality and delivery time, with the brand of Tomos, Star Citizen.

Contact US

We can custom made to any project unique Steel Structure Showroom with our professional technology and experienced sales & technical team.

- WhatsApp / Tel:+86 15995480121

- Email:[email protected]

- Room 103, 1st Floor, No. 82 Zhongta Road, Mudu Town, Wuzhong District, Suzhou, Jiangsu, China