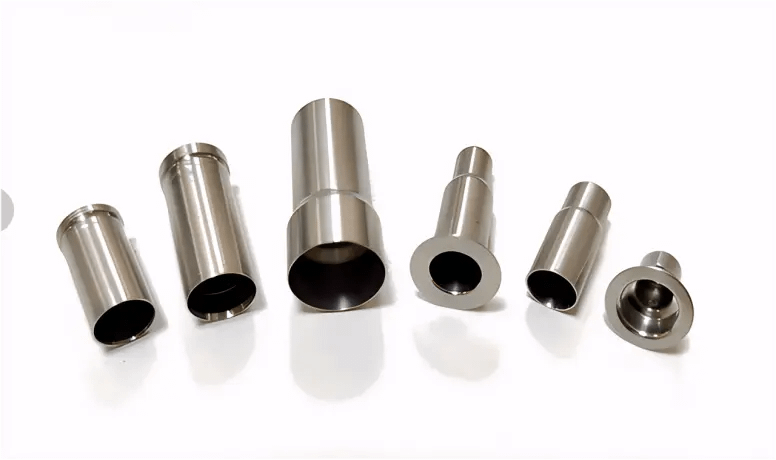

Stainless steel automotive oil pipe joint.

The automobile oil pipe joint is an indispensable and important component in the automobile oil system, used to connect the oil pipe and ensure the smooth flow of fuel or lubricating oil in the system. It not only needs to withstand high pressure, high temperature and corrosive media, but also must have excellent sealing performance and reliability to ensure the normal operation of the automobile engine.

- Good sealing performance: The automotive oil pipe joint can ensure good sealing performance even in high-pressure and high-temperature environments through precision machining and sealing structure design, preventing fuel or lubricant leakage.

- Strong pressure resistance: The joint needs to withstand the high pressure generated by the operation of the car engine, so having good pressure resistance is a basic requirement.

- Easy installation: For the convenience of maintenance and replacement, automotive oil pipe joints are usually designed with simple installation structures such as threaded connections and sleeve connections.

- Strong corrosion resistance: Due to the possibility of corrosive media flowing in the automotive oil system, joint materials need to have good corrosion resistance to extend their service life.

Feature:

Made via Stainless steel, carbon steel, copper alloy.Strong corrosion resistance, convenient installation, good sealing performance and strong pressure resistance.

Machining Precision:

The machining accuracy of automotive oil pipe joints has an important impact on their performance and service life. The machining accuracy of joints includes dimensional accuracy, shape accuracy and position accuracy. To ensure the high performance of joints, high-precision machining equipment and instruments such as precision CNC lathes need to be used in the machining process, and machining must be carried out in strict accordance with machining processes and requirements. After machining, the joints need to undergo strict quality inspection to ensure that various accuracy indicators meet the design requirements.

Machining Process:

The machining accuracy of automotive oil pipe joints has a significant influence on their performance and service life. Generally speaking, the machining accuracy of joints includes aspects such as dimensional accuracy, shape accuracy, and position accuracy. To ensure the high performance of joints, high-precision machining equipment and instruments, such as precision CNC lathes, need to be used in the machining process, and machining must be carried out in strict accordance with machining processes and requirements. After machining, the joints need to undergo strict quality inspection to ensure that various accuracy indicators meet the design requirements.

Product Application:

Automotive oil pipe joints are widely used in automotive oil circuit systems, such as fuel systems, lubrication systems, and cooling systems. They connect various components and pipelines to ensure the smooth flow of fuel or lubricating oil in the system and provide a strong guarantee for the normal operation of the automobile engine.

Elevate your manufacturing process with our specialized CNC machining service

Our cutting-edge technology and skilled team ensure that you receive high-quality components with exceptional strength and impact resistance.

Ideal for various applications, our UHMWPE parts combine performance with precision. Let us partner with you to push boundaries and innovate. Contact us to learn more about our capabilities and how we can support your business!

Our Team have focused on machining industry for 20 years,Production and sales of precision machinery parts,We have strong machinery manufacturing capacity, strong inspection equipment,mostof the parts were used for automotive.

The machines can meet your strict customized requirements for the machining tolerance , product quality and delivery time, with the brand of Tomos, Star Citizen. We have strong machinery parts manufacturing capacity, strong inspection equipment, most of the parts were used forautomotive,with the certification of lATF 16949. We provide a wide range of material options, the metal bars is our usual option, such as stainless steel, copper, brassaluminum and so on. Some multiple plastics is also our options.

Question and answer

OEM / ODM Services

Vacuum table

Rotary axis

Handwheel

Lubrication device

Tool Magazine

Spindle

Suzhou Changfei Precision Machinery Co., Ltd.

Why Clients Choose Us

ServicesOEM | Design | Buyer Label

Product lineAbove 10 production line

Total Employees80 - 120 People

Factory5,000-10,000 square meters

Customer Review

They accepted my request to use VHB tape for sticker,nice work,This is the mold to produce the part as my request.

Great prototype sample,Provide QC report and photos before shipping, nice service.

he CNC of the product is very superb and accurate, the surface is very clea.

Product arrived and it was perfect according to our engineer's measurements of the product.

Shipping Method

SHIP VIA EXPRESS DELIVERY

Ship products via sea