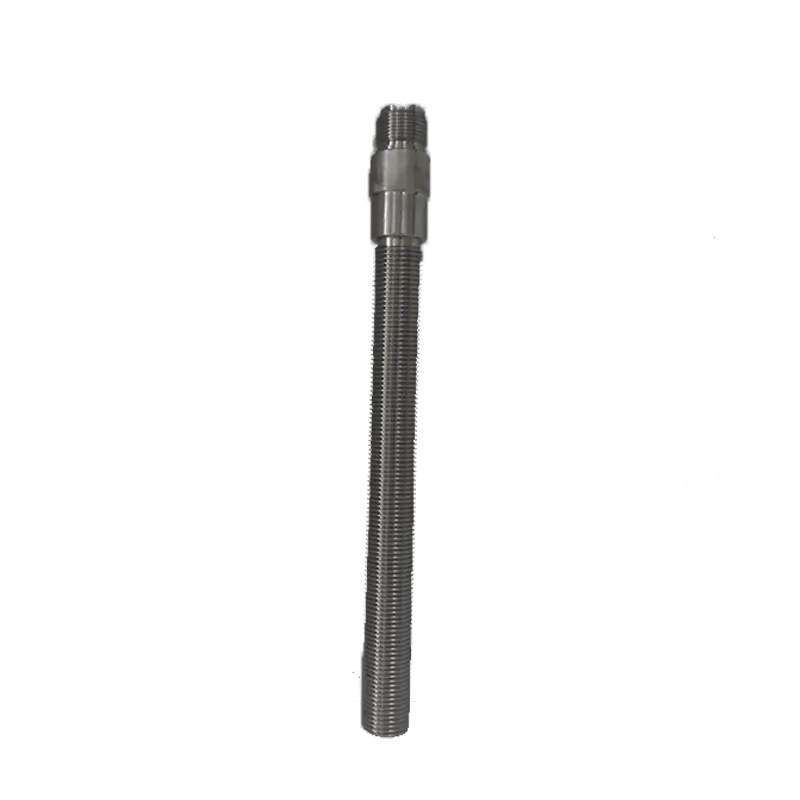

Hydraulic piston components.

Hydraulic pistons are widely used in various mechanical equipment, such as injection molding machines, die-casting machines, hydraulic presses, excavators, cranes, metallurgical equipment, etc. They play an important role in transmitting power, controlling motion direction and speed, and are essential components of hydraulic systems.

- Good sealing performance: The hydraulic system adopts precision machined sealing surfaces and high-quality sealing components to ensure leak free operation.

- High motion accuracy: The guiding belt and precision machined piston body ensure the linear motion accuracy of the piston in the hydraulic cylinder.

- Strong pressure bearing capacity: The hydraulic piston is made of high-strength materials and can withstand the impact and compression of high-pressure hydraulic oil.

- Long lifespan: The use of wear-resistant materials and reasonable structural design have extended the service life of hydraulic pistons.

- Easy maintenance: The structure of hydraulic pistons is relatively simple, making it easy to disassemble and replace damaged components.

Machining Precision:

The dimensional accuracy of hydraulic piston components should reach the micrometer level, with errors in straightness, flatness, and perpendicularity not exceeding a few micrometers. The surface roughness should be below Ra 0.4 micrometers, and the roundness and taper errors should also be less than a few micrometers. Additionally, positional accuracy errors between parts need to be controlled within a few micrometers. This level of precision ensures the overall performance and longevity of hydraulic piston components.

Machining Process:

In the processing of hydraulic piston components, a core drilling machine can achieve the completion of multiple machining operations with a single setup, significantly improving machining accuracy and production efficiency.

Based on the drawing requirements for hydraulic piston components, process analysis and design are conducted to determine the machining route, cutting parameters, and tool selection. By employing high-precision CNC systems and servo drive technology, micrometer-level machining accuracy can be achieved.

Multiple factors, including material, tooling, cutting parameters, and clamping methods, are comprehensively considered to ensure that the processed parts meet design specifications and operational requirements.

Product Application:

Hydraulic piston components have a very broad range of applications, almost covering all areas that require hydraulic transmission or control.

In the industrial sector, they are used in machine tools, metallurgical equipment, and construction machinery. In agriculture, hydraulic pistons are employed in agricultural machinery and irrigation systems. In the transportation sector, they play a vital role in automotive manufacturing, railway transport, and aerospace applications.

Their reliability and efficiency make them indispensable in these industries, ensuring smooth operation and control in various hydraulic systems.

Elevate your manufacturing process with our specialized CNC machining service

Our cutting-edge technology and skilled team ensure that you receive high-quality components with exceptional strength and impact resistance.

Ideal for various applications, our UHMWPE parts combine performance with precision. Let us partner with you to push boundaries and innovate. Contact us to learn more about our capabilities and how we can support your business!

Our Team have focused on machining industry for 20 years,Production and sales of precision machinery parts,We have strong machinery manufacturing capacity, strong inspection equipment,mostof the parts were used for automotive.

The machines can meet your strict customized requirements for the machining tolerance , product quality and delivery time, with the brand of Tomos, Star Citizen. We have strong machinery parts manufacturing capacity, strong inspection equipment, most of the parts were used forautomotive,with the certification of lATF 16949. We provide a wide range of material options, the metal bars is our usual option, such as stainless steel, copper, brassaluminum and so on. Some multiple plastics is also our options.

Question and answer

OEM / ODM Services

Vacuum table

Rotary axis

Handwheel

Lubrication device

Tool Magazine

Spindle

Suzhou Changfei Precision Machinery Co., Ltd.

Why Clients Choose Us

ServicesOEM | Design | Buyer Label

Product lineAbove 10 production line

Total Employees80 - 120 People

Factory5,000-10,000 square meters

Customer Review

They accepted my request to use VHB tape for sticker,nice work,This is the mold to produce the part as my request.

Great prototype sample,Provide QC report and photos before shipping, nice service.

he CNC of the product is very superb and accurate, the surface is very clea.

Product arrived and it was perfect according to our engineer's measurements of the product.

Shipping Method

SHIP VIA EXPRESS DELIVERY

Ship products via sea